Dredge Pipes, Steel and HDPE and assemblies

Steel dredge pipes

The dredge discharge line onshore typically consists of steel pipes along with any necessary fittings:

- Curves (bends)

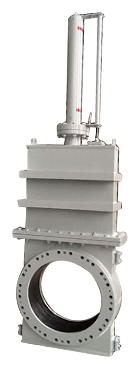

- Valves, managed by hand or hydraulicly

- Ball joints

- Spreaders

- Reducers

- Reclamation boxes

- Reducers

- Diffusers

- Etcetera

In waters, these pipes are made floating by floats and flexible by sleeves. Sinker lines are steel pipes welded in line and sunken down to the bottom.

HIGH DENSITY POLYETHYLENE (HDPE) dredging pipes

HDPE pipes possess long-term characteristics that make them resistant to corrosion, wear, and maintenance, suitable for use in seas, ponds, and rivers. The high-density polyethylene pipes are equipped with stub and steel flanges.

Applications:

- Dredge Pipe Lines.

- Water Transportation.

- Slurry Transportation.

- Floating Cable Casing Lines.

- Aquaculture breeding area cages.

Features:

- Made from PE 80 or 100 precompounded virgin material.

- Light weight – Easy installation.

- Flexible.

- Excellent Weathering & UV resistance.

- Ideal in combination with the DENIALINK PE Floats and sleeves.

- Pressure rating of PN 3.2 up to 25.

- Various diameters.

- All lengths, up to 20 meters.

- Color black.