Oil & Gas rubber hoses (OCIMF) for loading and discharge

Denialink collaborates with suppliers worldwide in high quality rubber hoses for loading and discharge of oil & gas and other substances.

The range of Hoses is in accordance with the lastest “OCIMF Guide to Purchasing, Manufacturing and Testing of Loading and Discharge Hoses for Offshore Moorings, Fifth Edition 2009 – GMPHOM 2009”.

Providing a range of high quality, high performance, oil suction and discharge hoses, extensively used at offshore moorings throughout the world, which fully comply with the requirements of the “OCIMF Guide to Purchasing, Manufacturing and Testing of Loading and Discharge Hoses for Offshore Moorings, Fifth Edition 2009 – GMPHOM 2009”. The Loading & Discharge hoses are available with rated working pressures of 15 BAR, 19 BAR and 21 BAR or higher for special applications or specific client requirements. The Single Carcass hose construction consists of three main elements; i) smooth bore elastomeric lining resistant to a variety of hydrocarbons, ii) a standard elastomer reinforced carcass with multi-layers of high tensile textile cords and embedded steel wire helix. iii) a fibre reinforced smooth elastomer cover, resistant to ageing, abrasion, weathering, sunlight, tearing oil and seawater penetration. In addition to the standard hose carcass (commonly termed ‘primary’ carcass), the Double Carcass hose incorporate an additional second carcass designed to contain any product escaping from the standard carcass as a result of a slow leak or sudden failure. An effective, robust and reliable, integrated leak detection and indication system is provided.

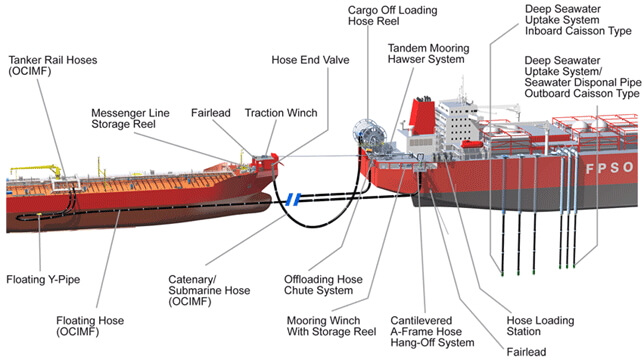

The Single Carcass and Double Carcass hose range includes hose construction for Floating, Submarine and Catenary applications, utilized in offloading installations worldwide EPS, MBM, SBM, CALM, SALM and Tandem Offloading.

- Single Carcass / Double Carcass Floating Hoses (utilized in high integrity surface installations such as EPS, SBM, CALM, SALM offloading in addition to FPSO, FSO Tandem offloading configurations).

- Single Carcass / Double Carcass Submarine Hoses (utilized in high integrity sub-sea installations such as MBM, SBM, CALM, SALM configurations (i.e. Steep ‘S’, Lazy ‘S’, Chinese Lantern).

- Single Carcass / Double Carcass Catenary Hoses (utilized in high integrity offloading installations subject to high tensile loads such as FPSO, FSO tandem offloading to DP Shuttle Tankers (i.e. BLS, Reel, Chute, Cantilever hang-off arrangements).

The Single Carcass and Double Carcass hose range is complemented by a comprehensive range of Ancillary Equipment, recommended within “OCIMF SPM Hose Ancillary Equipment Guide” publication.

For additional information on specific hose types and applications, please refer to availble hose data sheets.

Hoses fully comply with the requirements of the “OCIMF Guide to Purchasing, Manufacturing and Testing of Loading and Discharge Hoses for Offshore Moorings, Fifth Edition 2009 – GMPHOM 2009”.

Hoses are designed and manufactured under a quality system in accordance with ISO 9001:2015 and in compliance with ISO 45001 and ISO 14001..

Prototype Hose manufacture and testing witnessed and verified by ABS (Certifying Authority).